CONTROLLER FEATURE

:- High reliability as well as good resistance to plasma disturbance, lighting & surge.

:- Applied torch / plasma cutting technology, able to perform corner speed control &

Height control automatically.

:- Breakpoint restoration, automatic power-back recovery and automatic breakpoint

Memory,

:- Extended piercing for thick plate and bridging feature for thin plate.

:- Optional piercing position feature in mode of return , section ( section selection )

And resbrek ( breakpoint restoration ), very convenient for user control,

:- part library of 80 – type patterns, extensible and customizable , including

The common machining part.

:- compatible with many blanking software such as FAL CAM , FASTCAM, etc.

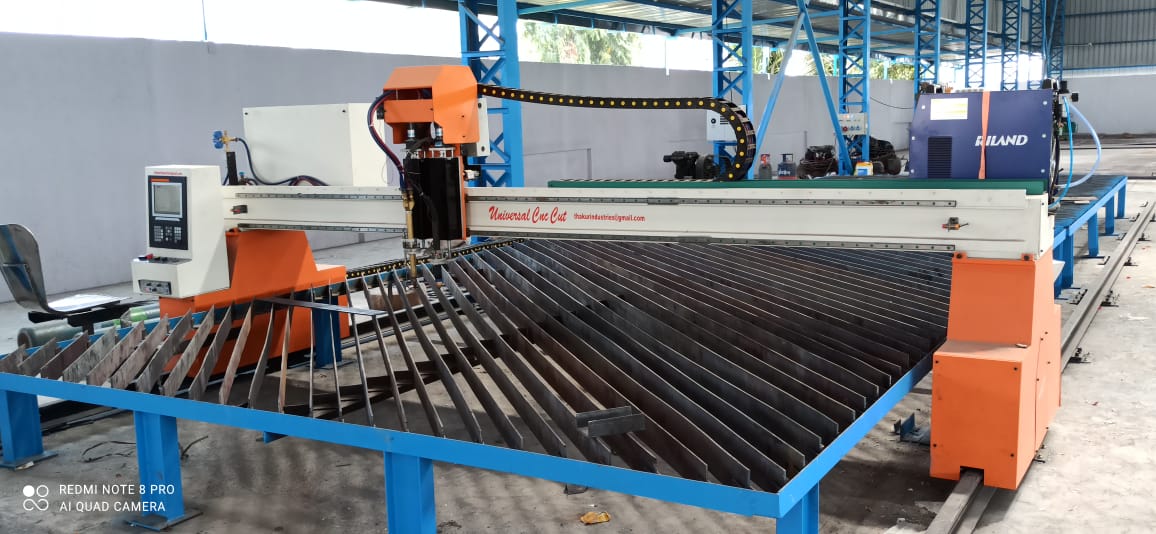

TECHNICAL SPECIFICATION:

:- Processor : Industrial ARM7 CPU.

:- Display : 7 “ color LCD

:- Input / output : 13 channels of optical isolation input and 8 channels of optical

Isolation output.

:- Interlocked axles : 2 axles , extensible to 4 interlocked axles.

:- Maximum speed : 24 m/min

:- Memory space : 32M-64M oversized memory capacity for user program and no

Restriction to machining program.

Brief Parameters

|

Input Voltage |

220V |

|

|

|

Power Frequency |

50/60Hz |

|

|

|

Max. Fuel Pressure |

0.1 Mpa |

|

|

|

Max. Combustive Gas Pressure |

1.5 Mpa |

|

|

|

Cutting Type |

Flame or Plasma |

|

|

|

Cutting Speed |

50 ~ 750 mm/min (flame); |

50 ~ 6000 mm/min(plasma) |

|

|

Cutting Thickness |

flame: 5 ~ 300 mm |

|

plasma : depends up on plasma power source |

|

Fuel |

Propane, Acetylene,LPG |

|

|

|

Cutting Precision |

0.2 mm |

|

|

|

Cutting Nesting Software |

FastCAM standard version |

|

|